Page Navigation

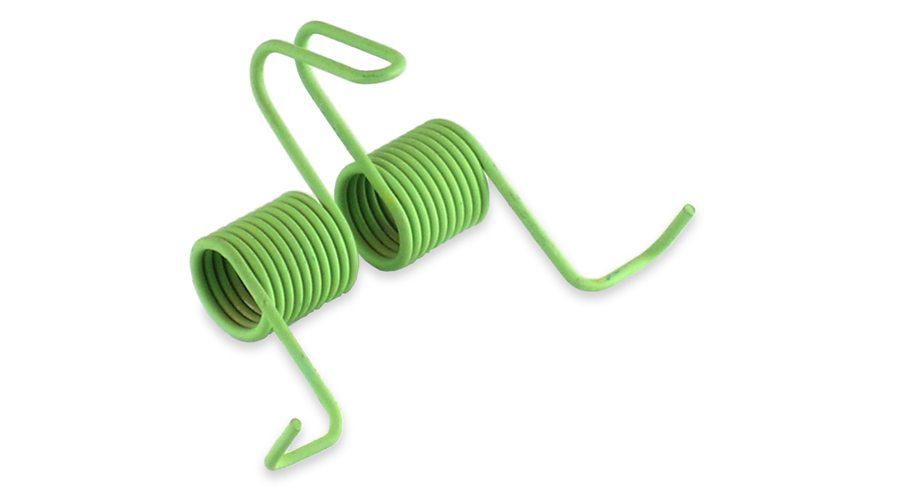

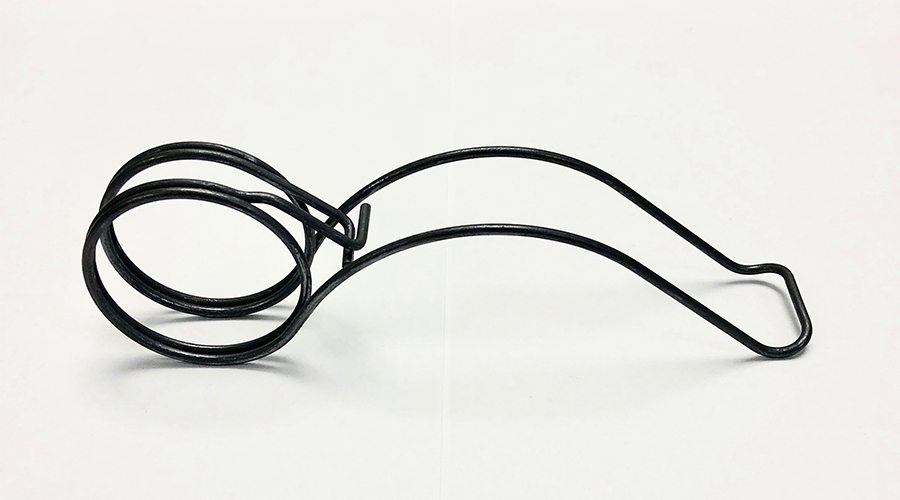

Torsion Springs

Key Product Highlights

Torsion springs are helical springs that apply a torque or rotary force and offer resistance to externally applied loads

The torque resulting from the angular deflection of the spring ends sets up bending stresses

Store and release angular energy by holding a mechanism in place allowing the tension to force the legs apart

Can be formed clockwise or counter-clockwise rotation, determining the direction of the wind.

Will reduce in body diameter and increase slightly in length when deflected in the preferred direction of the fabricated wind.

Can be built with tight coils or spaced out coils to reduce friction

Can be made from round, rectangular, square or special cross-section wire

Wire diameter .005” to .626”

Spring legs can be bent, hooked, or formed to conform to custom application

Torsion Springs

MATERIALS, USAGE & SPECIFICATIONS

We most commonly use the following types of alloys in our flagship and custom products: carbon steel, alloy steel, stainless steel, nickel-based, cobalt-based, copper-based, and titanium. To view our full materials list, click on the click below.

View Materials ListCommercial Aviation & Space

Explore Industry >>

Defense

Explore Industry >>

Energy, Gas & Mining

Explore Industry >>

General Manufacturing

Explore Industry >>

Medical

Explore Industry >>

Nuclear

Explore Industry >>